Blog

Why Choose a Roll Lamination Machine for Your Business Needs?

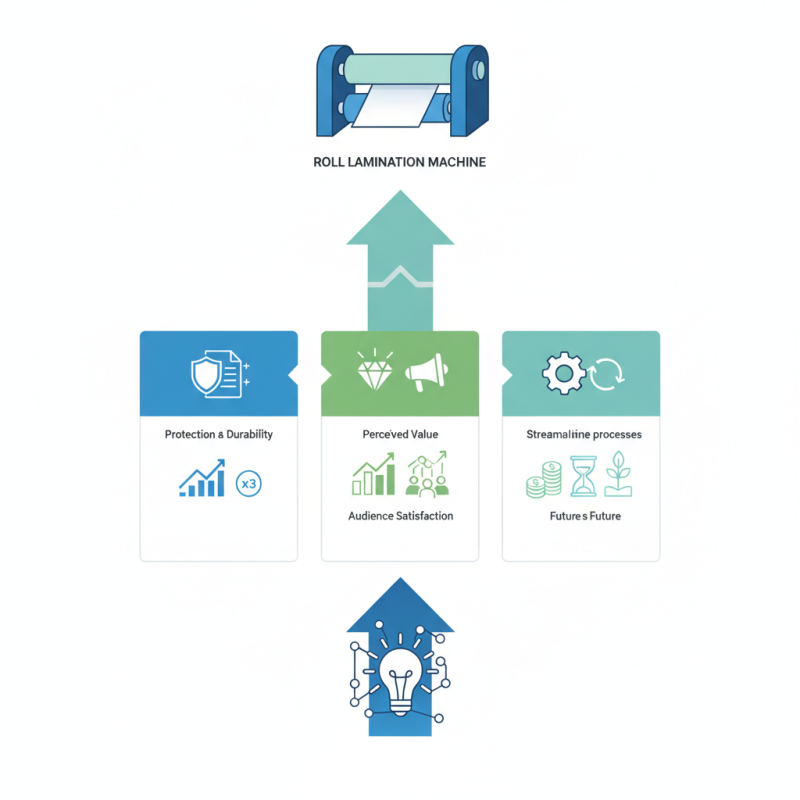

In today's competitive landscape, businesses often seek effective solutions for efficient production. The "Roll Lamination Machine" is a valuable tool that enhances durability and presentation of materials. Industry reports indicate that laminated products can last up to three times longer than non-laminated ones. This data shows the importance of investing in quality machinery.

John Smith, a leading expert in lamination technology, states, "A Roll Lamination Machine transforms ordinary materials into high-impact products." This transformation can significantly elevate a business's offerings. However, many companies overlook this potential, resulting in subpar presentations. They may not realize that the right equipment can streamline processes and reduce long-term costs.

Investing in a Roll Lamination Machine is not just about equipment; it's about future growth. Businesses must reflect on their current practices and consider how improved lamination can set them apart. The right choice today can lead to enhanced efficiency and higher customer satisfaction tomorrow.

Benefits of Using a Roll Lamination Machine in Business Operations

In today’s fast-paced business environment, efficiency is key. A roll lamination machine can enhance your operations significantly. It protects documents and materials from wear and tear. The lamination process seals edges tightly, preventing moisture and dirt from causing damage. This is crucial for businesses that rely on maintaining high-quality presentations.

Cost-effectiveness is another important factor. Such machines can reduce the need for frequent reprinting, saving both time and money. When documents look professional, they create a better impression. However, initial investments can be high. It’s essential to weigh costs against long-term benefits realistically.

Moreover, while these machines streamline processes, they require regular maintenance. Neglecting upkeep can lead to operational hiccups. Training staff to use the equipment correctly is vital, yet often overlooked. An undertrained staff could hinder efficiency. Adapting to new technology can be challenging, but the rewards may surpass the hurdles.

Overview of Roll Lamination Technology and Its Applications

Roll lamination technology is transforming businesses across various sectors. This process involves encapsulating materials in a thin layer of plastic, enhancing durability and protection. Recent industry reports indicate that the global market for laminating machines is projected to reach approximately $2 billion by 2025. This growth is a clear sign of increasing demand.

Applications are widespread. Businesses in sectors like education, healthcare, and retail benefit from roll lamination. For instance, documents and promotional materials are preserved for longer periods. A study by market research firms shows that products with lamination experience a 30% increase in lifespan. This improvement can be critical for companies that rely on high-quality presentations.

However, there are challenges. Not every material is suitable for lamination. Some substrates may warp or buckle during the process. Training staff to operate the machines effectively is also essential. Poor handling can lead to significant waste, affecting production costs. It’s vital to understand the limitations. A thoughtful approach is necessary for successful implementation of roll lamination technology in any business setting.

Advantages of Roll Lamination Technology

Key Features to Consider When Selecting a Roll Lamination Machine

When selecting a roll lamination machine, various features matter significantly. Speed is key. Many machines operate at up to 20 meters per minute. Higher speeds increase productivity, but consider the quality. A faster machine may sacrifice finish quality if set incorrectly. Look for user-friendly controls. Intuitive settings can minimize operator errors.

Another critical feature is the temperature control. Consistent heating ensures even lamination. Machines with digital displays allow for better temperature management. A recent industry report indicates that proper temperature regulation can enhance adhesion by up to 30%.

Tips: Always check warranty options. Some machines offer limited warranties, covering parts but excluding labor. It's wise to read reviews about support services as well.

Material thickness compatibility is another consideration. Ensure your machine can handle varying thicknesses for diverse projects. Some machines might struggle with thicker materials. This might lead to poor lamination and increased waste. Research proves that up to 15% of costs can stem from material mishandling.

Investing time in understanding these features can significantly impact your operations. Aim for a balance between speed, quality, and versatility.

Cost-Effectiveness of Roll Lamination for Various Industries

Roll lamination offers significant cost-effectiveness across various industries. Many businesses find that investing in a roll lamination machine streamlines their operations. This technology can reduce labor costs and waste. With roll lamination, companies can produce durable, high-quality items quickly and efficiently.

For example, packaging companies benefit greatly from this process. They can create protective coverings that extend product life. This leads to less product loss and greater customer satisfaction. In addition, education materials can be laminated easily, giving them a longer shelf life. However, businesses must consider maintenance costs. Overlooking this could affect the overall savings.

Some challenges exist in the initial setup. Training staff on new machines can take time. If employees are not properly trained, mistakes may happen. This could lead to wasted materials and increased expenses. Therefore, weighing the pros and cons before investing is crucial. Understanding these nuances can help businesses make informed decisions.

Future Trends in Roll Lamination Technology and Business Impact

The roll lamination industry is evolving rapidly. Recent studies project a growth rate of 7.5% annually through 2028. This trend reflects the increasing demand for high-quality lamination solutions across various sectors. Businesses are seeking machines that not only improve efficiency but also reduce waste. Innovations in technology are shaping these machines to meet the precise needs of manufacturers.

One significant trend is the integration of digital solutions. Companies are exploring automated roll lamination systems. These systems offer real-time monitoring and data analysis. They can potentially enhance productivity by 20%, according to industry reports. However, transitioning to digital solutions requires a thoughtful approach. Not every business is ready to adopt such technology due to costs and training needs.

Sustainability is another core focus. The pressure to reduce carbon footprints is growing. Companies are looking for eco-friendly materials in lamination processes. The challenge lies in balancing performance and environmental impact. Not all machines can efficiently handle biodegradable or sustainable materials. This gap presents an opportunity for further research and development. Businesses may need to rethink their strategies to adapt effectively.