Blog

What is a Hydraulic Hose for Sale and How to Choose One?

In industrial applications, choosing the right hydraulic hose for sale is crucial. Experts like John Smith, a veteran in the hydraulics industry, emphasize, “Quality makes all the difference.” This statement highlights the importance of selecting hoses that can withstand extreme pressures and environments.

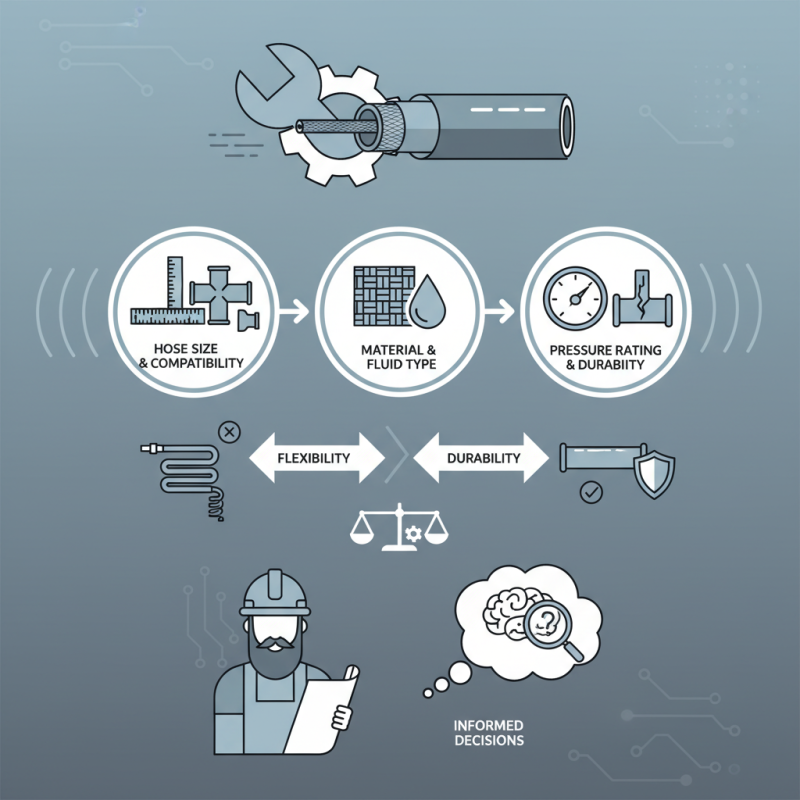

When looking at hydraulic hoses for sale, several factors come into play. Users must consider hose size, material, and pressure ratings. Not all hoses are created equal, and the wrong choice can lead to leaks or failures. It's easy to overlook details like compatibility with existing systems. Each component must work together seamlessly.

Additionally, while options abound, the perfect hose may not exist. Companies often face trade-offs between flexibility and durability. Reflecting on these choices can help avoid costly mistakes. Buyers should seek guidance, yet trust their instincts. After all, making informed decisions can significantly impact performance and safety.

What is a Hydraulic Hose and Its Key Components Explained

Hydraulic hoses are crucial in various hydraulic systems. They transport fluids under pressure to different components, enabling machinery to function effectively. A typical hydraulic hose consists of three key components: the inner tube, reinforcement layer, and outer cover. The inner tube carries the fluid, while the reinforcement layer provides strength. The outer cover protects the hose from external damage.

Tips: When choosing a hydraulic hose, consider the pressure rating. It’s essential to select a hose that can handle the maximum pressure in your system. A mismatch can lead to system failures. Pay attention to the hose diameter, as well. Too small a diameter can restrict fluid flow.

Not all hoses are created equal. Factors like temperature and fluid type matter. Some fluids can degrade certain materials. It's vital to check compatibility to avoid leaks or bursts. If unsure, consult with an expert. Understanding the specific requirements of your application helps in selecting the right hose. Choose wisely, as it can impact performance.

Types of Hydraulic Hoses Available on the Market Today

Hydraulic hoses are crucial components in many machinery and equipment. They carry fluids under high pressure, enabling efficient operation. When looking for hydraulic hoses available today, understanding the types can greatly benefit your selection process.

There are several types of hydraulic hoses. The most common include rubber, thermoplastic, and stainless steel hoses. Rubber hoses are flexible and durable. They withstand high pressure and temperature but may degrade faster in harsh environments. Thermoplastic hoses are lighter and resistant to abrasions. However, they can be less flexible than rubber. Stainless steel hoses offer excellent resistance to corrosion and high pressure but tend to be heavier and more expensive.

Choosing the right hydraulic hose can be tricky. It’s essential to consider factors like pressure ratings and environmental conditions. Think about how the hose will be used. Will it bend often or face extreme temperatures? Each situation requires a different approach. Therefore, consulting with an expert or doing thorough research is beneficial. Don’t rush the decision; a wrong choice can lead to costly repairs or failures.

Factors to Consider When Selecting a Hydraulic Hose

When selecting a hydraulic hose, several factors warrant consideration. The hose's intended application plays a vital role. Different tasks may require varying pressure ratings, making it crucial to match the hose to specific needs. For instance, heavy machinery requires a robust hose that can withstand increased pressure. In contrast, lighter tasks may require a less durable option.

Additionally, the size of the hose is critical. It must fit the application while ensuring proper flow. A hose too large can lead to inefficiencies. Conversely, a small hose may restrict fluid movement, causing failures. Material is another factor. Hoses made from different materials offer various benefits. Some may be more resistant to heat, while others withstand harsh chemicals.

Don't overlook the hose type. Rubber, thermoplastic, and spiral wire options exist. Each serves unique purposes based on flexibility and durability. Sometimes, mixing types might seem tempting to save costs. However, hasty decisions can lead to premature failures, affecting overall performance.

Remember, investing time to evaluate these aspects can make a significant difference in the long run.

Industry Standards and Regulations for Hydraulic Hoses

When selecting a hydraulic hose, it's crucial to consider industry standards and regulations. These guidelines ensure safety and performance. Different sectors, like construction and agriculture, have established specific requirements for hydraulic hoses. Following these standards helps prevent failures and accidents.

One key regulation is the use of standardized specifications. For instance, hoses should meet minimum pressure ratings. Understanding the pressure limits is vital. If a hose is under-specified, it may burst. This could cause extensive damage. Also, hose materials must comply with environmental factors. Temperature and chemical exposure affect durability. Choosing the wrong material can lead to premature wear.

Testing and certification are other important aspects. Hoses often undergo rigorous testing to ensure they meet industry standards. However, not all manufacturers adhere to these tests. Buyers should check for proper certifications before making a purchase. Sometimes, it’s easy to overlook this detail, but it’s essential. Failing to recognize the importance of certification can result in costly mistakes down the line.

Maintenance Tips for Extending the Lifespan of Hydraulic Hoses

Hydraulic hoses are critical components in various industries, serving to transmit hydraulic fluid under pressure. To extend their lifespan, regular maintenance is essential. A report by the National Fluid Power Association indicates that improper maintenance can reduce the operational life of hydraulic hoses by up to 50%. Regular inspections for leaks, abrasions, and signs of wear can significantly mitigate issues before they escalate.

Cleaning hydraulic hoses is also important. Contaminants can damage hose materials and compromise safety. According to a study published by the International Organization for Standardization, maintaining cleanliness can reduce hose failure rates by as much as 30%. Implementing a routine where hoses are wiped down after use helps. Using protective sleeves can prevent external damage, which is often overlooked.

Lastly, be aware of the operating environment. Extreme temperatures and exposure to harsh chemicals can degrade hoses rapidly. A study revealed that hoses exposed to temperatures beyond their limits could fail in as little as six months. Employing temperature-resistant hoses in challenging conditions can be a game-changer. However, it’s crucial to remember that even the best hoses need monitoring, as issues can arise unexpectedly. Regularly revisiting maintenance practices keeps systems running smoothly and should not be neglected.