Blog

What is a Damper Actuator and How Does It Work?

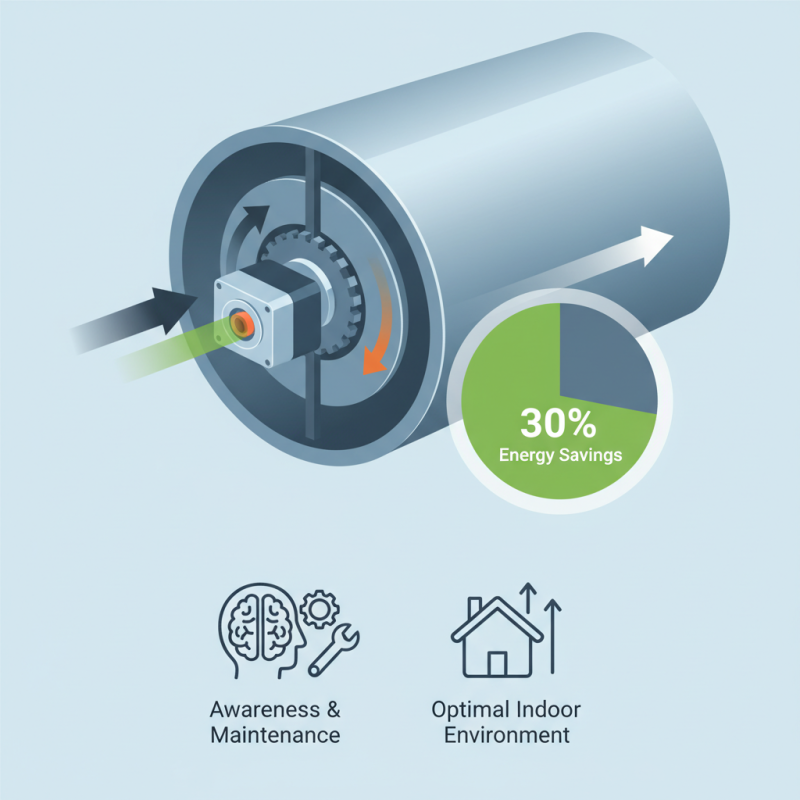

The Damper Actuator is a crucial component in HVAC systems, regulating airflow and enhancing energy efficiency. According to a report published by the International Energy Agency, optimizing such systems can reduce energy consumption by up to 30%. This highlights the importance of damper actuators in modern building design.

Renowned expert Dr. Emily Carter states, "Effective airflow control is key to both comfort and energy savings." Her perspective emphasizes how damper actuators play a vital role in achieving optimal indoor environments. With the increasing demand for energy-efficient systems, understanding their mechanics is essential.

Despite advancements, the industry faces challenges. Many installations suffer from misconfigurations and inadequate maintenance. This often leads to suboptimal performance. Awareness and education about damper actuators can mitigate these issues, fostering better HVAC practices.

What is a Damper Actuator?

A damper actuator is a crucial component in HVAC systems. It controls airflow by adjusting the position of dampers. These dampers can be found in air ducts, allowing precise regulation of air distribution. This ensures optimal comfort levels in buildings. In fact, studies show that efficient airflow can improve energy savings by up to 30%.

The operation of a damper actuator usually involves an electric or pneumatic drive. A typical electric actuator uses a motor to open or close the damper blades. This action enables the system to respond quickly to changes in demand. For instance, if a room gets too warm, the actuator can close the damper to reduce airflow. However, it’s important to note that improper calibration may lead to inefficient operation.

While damper actuators are essential, they are not without their challenges. Issues such as electrical failure or mechanical wear can hinder performance. Consequently, regular maintenance is necessary to ensure they function correctly. Studies indicate that more than 20% of HVAC systems experience issues related to damper actuators. Regular inspections can help in identifying problems early.

What is a Damper Actuator and How Does It Work? - What is a Damper Actuator?

| Feature | Description |

|---|---|

| Function | Regulates airflow in HVAC systems by opening and closing dampers. |

| Types | Electric, pneumatic, and hydraulic actuators. |

| Control Methods | On/Off, modulating (varying positions based on demand). |

| Applications | Used in commercial and residential HVAC systems, industrial processes. |

| Benefits | Improves energy efficiency, enhances comfort, reduces wear on HVAC systems. |

| Installation | Typically mounted on air ducts, requires professional setup for complex systems. |

| Maintenance | Regular checks ensure proper functioning and longevity of the actuator. |

Types of Damper Actuators Explained

Damper actuators play a crucial role in regulating airflow and maintaining environmental comfort in buildings. There are mainly two types of damper actuators: electric and pneumatic. Electric actuators use motors to open or close dampers in response to control signals. They offer precision and can be integrated with smart systems. Pneumatic actuators utilize compressed air for operation. These actuators are reliable and often used in larger systems.

Understanding each type is important for effective application. Electric actuators are generally easier to install. However, they require a constant power supply. This might be a concern during power outages. On the other hand, pneumatic actuators need air pressure to function. This can be a limitation in certain situations. Still, they can handle larger dampers efficiently.

Some users prefer one type over the other. This choice often depends on system design and operational needs. Each actuator type has its strengths and challenges. Recognizing these can lead to better decision-making in environmental control systems. It’s crucial to evaluate specific needs before selecting a damper actuator.

How Damper Actuators Function Mechanically

Damper actuators play a crucial role in controlling airflow in HVAC systems. They regulate the position of dampers, which manage the movement of air in ducts. Mechanical function is key here. Most actuators work through a simple yet effective mechanism. A motor drives the actuator, changing its position based on control signals. This allows for precise airflow adjustments, improving energy efficiency.

A study by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) indicates that housing a damper actuator can lead to a 15-25% reduction in energy consumption in commercial buildings. The linear movement of the actuator is often achieved using gears or levers. This mechanical action translates electrical signals into physical movement, crucial for optimal system performance. However, improper calibration can lead to inefficiencies.

Another aspect to consider is actuator responsiveness. Mechanical fatigue can affect performance over time. Regular maintenance can counteract this issue. Research suggests that about 30% of HVAC energy loss is due to improperly functioning dampers. Evaluating the condition and responsiveness of damper actuators is necessary. After all, a malfunctioning actuator can lead to uneven temperatures and increased costs.

Applications of Damper Actuators in HVAC Systems

Damper actuators play a crucial role in HVAC systems. They control the airflow within ducts. This ensures the right amount of air reaches each room. An efficient damper actuator adjusts dampers automatically. It responds to temperature changes and occupancy. This feature adds comfort and efficiency to indoor environments.

In commercial buildings, damper actuators can optimize energy use. By regulating airflow, they reduce heating and cooling loads. This can lower energy bills significantly. In residential settings, they improve air quality. However, regular maintenance is essential. Dust and debris can hinder their performance. If neglected, they may lead to uneven temperatures.

With the advancement of smart technology, damper actuators are becoming more sophisticated. They can integrate with building management systems. This allows for precise control and monitoring. Yet, technology can fail. It's crucial to have backup systems in place. Continuous improvements and assessments are necessary for peak performance.

Applications of Damper Actuators in HVAC Systems

Maintenance Tips for Damper Actuators

Maintaining damper actuators is essential for optimal performance. These devices regulate airflow and ensure efficient operation. Regular checks can prevent issues before they escalate. Inspect the actuator for signs of wear or damage. Look for loose connections that might disrupt functionality. Dust and debris can also impact performance, so keep the area clean.

Lubrication is critical but often overlooked. Apply lubricant to moving parts sparingly. Too much can attract more dust and lead to problems. Monitor the actuator's response time. If it operates sluggishly, that could signal a need for maintenance. Remember, even minor irregularities may lead to larger, costly repairs.

Revisiting routines regularly is essential. Schedule maintenance according to usage. Document each inspection for future reference. This can help identify patterns or recurring issues. While maintenance may seem tedious, it's worthwhile for long-term efficiency. A proactive approach saves time and resources in the long run.