Blog

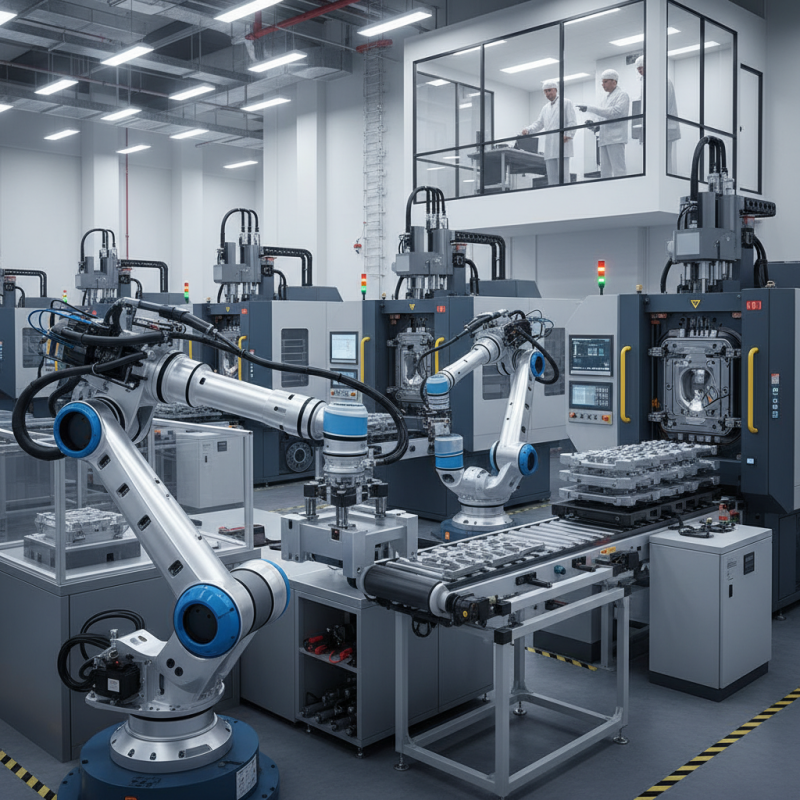

How to Choose the Right Injection Machine Robot for Your Needs?

Choosing the right Injection Machine Robot is a crucial decision for any manufacturing operation. The variety of options available can be overwhelming. Each robot offers different features and capabilities. It’s important to evaluate specific needs before making a choice.

Consider factors like payload capacity and precision. Some applications require heavy lifting, while others focus on accuracy. Think about the speed and flexibility needed for your production line. An Injection Machine Robot should fit seamlessly into your existing setup. Reflecting on the particular context of your operations will lead to better choices.

Keep in mind the potential shortcomings of each model. Not every robot may meet your expectations completely. Gaps in performance can impact efficiency. It’s essential to weigh the pros and cons carefully. Investing time in research will yield better results in the long run.

Understanding the Types of Injection Machine Robots Available

When selecting an injection machine robot, understanding the available types is crucial. There are primarily four types: Cartesian, SCARA, articulated, and delta robots. Each type has its unique benefits and shortcomings.

Cartesian robots excel in linear movements, ensuring accuracy in applications like material handling. They can be easier to maintain but may lack flexibility in complex tasks.

SCARA robots are known for their speed and precision. They work well for applications needing quick and repetitive actions. However, their reach can be limited, affecting their usability in larger setups.

Articulated robots, on the other hand, mimic human arm movements. They offer flexibility but can be tricky to program, especially for complex tasks.

Delta robots stand out for high-speed operations. They are perfect for assembly and pick-and-place tasks. Yet, their design may limit their capacity for heavier loads. Assessing your specific needs alongside these types can lead to more effective choices. Each option comes with trade-offs. Reflecting on these aspects is essential for making an informed decision.

Assessing the Specifications and Features of Injection Robots

When selecting an injection machine robot, evaluating specifications and features is vital. Pay close attention to payload capacity. Determine what weight your robot will lift. A mismatch can lead to operational issues.

Speed and precision are crucial too. Look for robots that offer different speed settings for various tasks. Fast operations can boost productivity. However, ensure that speed does not compromise accuracy, especially for intricate designs.

Tips: Always read user reviews. Feedback from existing users can provide valuable insights. Consider future needs when selecting a robot. Investing in a versatile model might save costs later.

Another aspect to consider is ease of programming. A user-friendly interface is essential for quick adjustments. Complicated systems can frustrate operators and slow down production. Assess whether the robot supports various programming languages or is compatible with your current systems. This aspect might not seem important, but it can affect your workflow significantly.

Evaluating Your Injection Molding Production Needs

When evaluating your injection molding production needs, consider the scale of your operation. Are you producing small batches or large volumes? Smaller operations may not need high-capacity machines. In contrast, large-scale production could benefit from faster cycle times and higher precision. Analyzing production goals helps align your robot selection with operational requirements.

Next, assess the types of materials used in your processes. Different materials may require different handling capabilities. Some machines offer enhanced compatibility with specific resins. Take note of any limitations in your current setup. Identifying these can improve efficiency, but it may reveal a need for upgrades.

Lastly, think about the space and flexibility available in your facility. A larger robot may offer more capabilities but can also take up valuable floor space. If your layout is tight, compact machines might be a better fit. Balancing functionality and space is key. This approach may uncover hidden issues, urging you to rethink your production layout.

Budget Considerations When Choosing Injection Machine Robots

When selecting injection machine robots, budget plays a critical role. The initial purchase price often overshadows other essential costs. A report by BCC Research states that the global robotic arm market is expected to surpass $20 billion by 2025. This indicates a growing trend, but it also means making a thoughtful financial decision is crucial.

While it's tempting to opt for low-cost robots, they may lack reliability. A report from Mordor Intelligence highlights that cheaper models often have higher maintenance costs. In fact, 30% of organizations reported unexpected repairs leading to downtime. A slight increase in initial investment can yield better performance and longer lifespan, providing peace of mind.

Considering all costs is vital. Installation and training fees can add up quickly. Industry data shows that a significant portion of users underestimated these expenses. In some cases, robotic systems may require specialized skills for effective operation. Budgeting for these factors can prevent future headaches. Reflecting on these details now can lead to better choices later.

How to Choose the Right Injection Machine Robot for Your Needs? - Budget Considerations When Choosing Injection Machine Robots

| Robot Type | Payload Capacity (kg) | Reach (mm) | Cycle Time (s) | Price Range ($) |

|---|---|---|---|---|

| Standard 6-Axis Robot | 5-10 | 600-800 | 1.2 | 25,000 - 35,000 |

| High-Speed Delta Robot | 3-6 | 400-600 | 0.5 | 30,000 - 45,000 |

| Cartesian Robot | 10-20 | 800-1200 | 1.5 | 20,000 - 30,000 |

| Collaborative Robot (Cobots) | 3-5 | 500-700 | 1.0 | 15,000 - 25,000 |

| Specialized Robotics Solutions | Variable | Variable | Variable | 50,000+ |

Maintenance and Support Options for Injection Robot Systems

Maintenance of injection robot systems is crucial for optimal performance. Regular check-ups can prevent costly downtime. It’s important to establish a routine schedule for maintenance tasks. Often, minor issues escalate into major problems if ignored. Wear and tear can affect precision and speed during production.

Support options vary widely. Some manufacturers provide on-site assistance, while others rely on remote monitoring. Understanding your needs can help determine the best support type. Quick response times are vital. An accessible support team can minimize disruption. Don’t overlook user manuals; they are valuable resources for troubleshooting.

Many users face challenges with maintenance guidelines and schedules. Customizing maintenance plans may be necessary due to specific operational conditions. Keep in mind, regular training for staff can improve machine handling and maintenance awareness. Gaps in knowledge can lead to errors and inefficiencies. Continuous feedback from your team is essential to refine support and maintenance strategies.