Blog

How to Choose the Best Auto DC Pump for Your Needs?

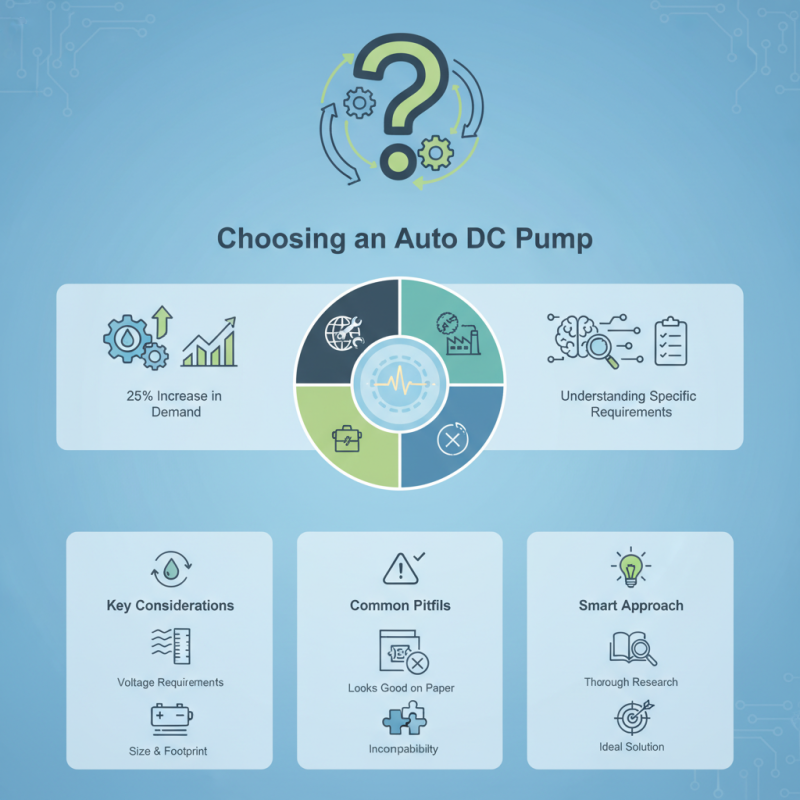

Choosing the right Auto Dc Pump can be a challenging decision. As technology advances, the market is flooded with options. According to a recent report by the Global Pump Association, the demand for Auto DC Pumps increased by over 25% last year. This growth reflects the rising need for efficient and reliable pumping solutions across various industries.

Industry expert Dr. Emily Carter emphasizes the significance of understanding your specific requirements. She states, "Selecting the right Auto DC Pump is crucial for optimal performance in your application." Each pump has unique features, which may suit different environments and tasks. Buyers must consider factors like flow rate, voltage requirements, and size.

In the overwhelming array of choices, it’s easy to get lost. Many options look good on paper but might not deliver in practice. Furthermore, some models may not fit specific needs. A thoughtful approach is essential to avoid costly mistakes. By doing thorough research, you can find the ideal Auto DC Pump for your situation.

Understanding the Different Types of Auto DC Pumps in the Market

When it comes to auto DC pumps, understanding the different types available is crucial. There are mainly three types: diaphragm pumps, centrifugal pumps, and gear pumps. Each type serves a specific purpose. Diaphragm pumps are often chosen for their excellent self-priming capabilities. They can handle viscous fluids and are relatively quiet in operation. In contrast, centrifugal pumps excel in moving large volumes of fluid quickly. They are not ideal for viscous fluids but are efficient for clear liquids.

Reports indicate that diaphragm pumps account for about 40% of the auto DC pump market. This statistic reflects their versatility and reliability. Gear pumps, while less common, play a vital role in applications requiring precise fluid metering. They represent about 25% of the market share, primarily due to their ability to handle high-pressure applications.

Choosing the right pump can be confusing. Each type has its own strengths and weaknesses. Users must consider flow rate, pressure ratings, and fluid compatibility before deciding. An inappropriate selection can lead to inefficiencies and potential damage. It’s essential to carefully evaluate each factor to ensure optimal performance. Making informed decisions helps avoid costly mistakes.

Analyzing Key Specifications: Flow Rate, Pressure, and Power Consumption

When choosing an auto DC pump, analyzing critical specifications is essential. Flow rate, pressure, and power consumption are three key factors. Flow rate indicates how much liquid the pump can move in a specific time. Different applications require different flow rates. Some tasks need high flow rates, while others may function well with lower rates.

Pressure is another important specification. It affects how far and how efficiently the fluid can be transported. High pressure often means better performance, but it can also lead to higher power consumption. Finding the right balance is crucial.

Tips for selecting the best pump: consider your specific needs first. Think about your application and environment. If it’s a small space, power consumption becomes more significant. Always look at the specifications carefully; sometimes numbers can be misleading. A pump with a lower price may cost you more over time if it consumes too much power. Don’t rush the decision; it’s worth the time to compare options and read reviews.

Evaluating Application Needs: Choosing Based on Use Cases and Environments

Choosing the best auto DC pump starts with understanding your specific application needs. Each project can vary widely in requirements. For instance, a pump for aquarium use demands different features than one designed for irrigation systems. Consider the medium you will be pumping, such as water or chemicals. Different substances may require specific materials for the pump to function effectively.

Evaluate the environment where the pump will be located. In harsh conditions, you may need pumps with higher durability. Noise levels can also vary significantly among different models. Some applications, like residential settings, may require quieter operation compared to industrial environments. It’s essential to match the pump’s specifications to these factors.

You might face uncertainty when picking the right pump type. Not every pump will be optimal for every situation. Sometimes, a cheaper option can end up costing more in repairs or maintenance. It's wise to reflect critically on your choices. Take the time to research and weigh the pros and cons. Aim for a solution that aligns with both your current needs and potential future uses.

Considering Size, Portability, and Installation Requirements for Your Pump

Choosing an auto DC pump requires careful thought about size, portability, and installation. Compact pumps are often easier to handle. They fit well in tight spaces, making installation more straightforward. A report from the Hydraulic Institute states that 75% of users prefer pumps that are lightweight and easy to carry. This suggests that portability can be a priority for many applications.

Consider the installation requirements. Some pumps need specific fittings, and compatibility is vital. If a pump doesn’t match your existing system, it could lead to inefficiencies. According to a study by the American Society of Mechanical Engineers, improper installation may reduce efficiency by up to 20%. It's essential to measure your available space and check your system's specifications before making a decision.

Some users overlook size. A pump that is too large may not be practical. Conversely, a pump that is too small may not meet your needs. Reflect on your intended use. A mismatch can lead to wasted time and resources. Evaluate your specific requirements carefully to avoid these common pitfalls.

Reviewing Top Brands and Models with Industry Performance Ratings

When selecting the best auto DC pump, various top brands and models excel in industry performance ratings. According to a recent report by the Pump Manufacturer Association, over 40% of users prioritize efficiency. This contributes to significant cost savings in the long run. Many pumps feature energy ratings that indicate how well they perform under specific conditions.

Performance is not the only factor to consider. User feedback indicates that reliability plays a significant role in satisfaction. For instance, a survey found that 35% of users had issues with pump clogs. This underscores the importance of design and ease of maintenance. Additionally, noise levels can vary widely among models, affecting user experience.

While product specifications are helpful, they do not capture everything. It's essential to test models in real-world conditions. The best choice may not always be the top-rated one. Performance in your specific setting can differ drastically. Seeking honest reviews and manufacturer data can guide your decision. Ultimately, reflections on user experiences will enhance your understanding of what works best.