Blog

How to Choose Die Casting Molds for Your Projects?

Choosing the right Die Casting Molds is crucial for project success. According to a recent industry report by the Die Casting Association, molds can account for up to 30% of the total production cost. Selecting the right mold influences not only cost but also production efficiency and product quality.

John Smith, a leading expert in die casting, emphasizes the importance of understanding material properties. He states, "The choice of die casting molds directly impacts the longevity and functionality of the final product." This underscores the need for careful consideration in the selection process.

Many companies struggle with mold choices. They often overlook the significance of mold design and material selection. Inadequate research can lead to issues such as premature wear and increased downtime. An informed decision can prevent costly mistakes. Ultimately, effective selection of Die Casting Molds requires thoughtful analysis and expert guidance to achieve optimal results.

Understanding Die Casting Molds and Their Functionality

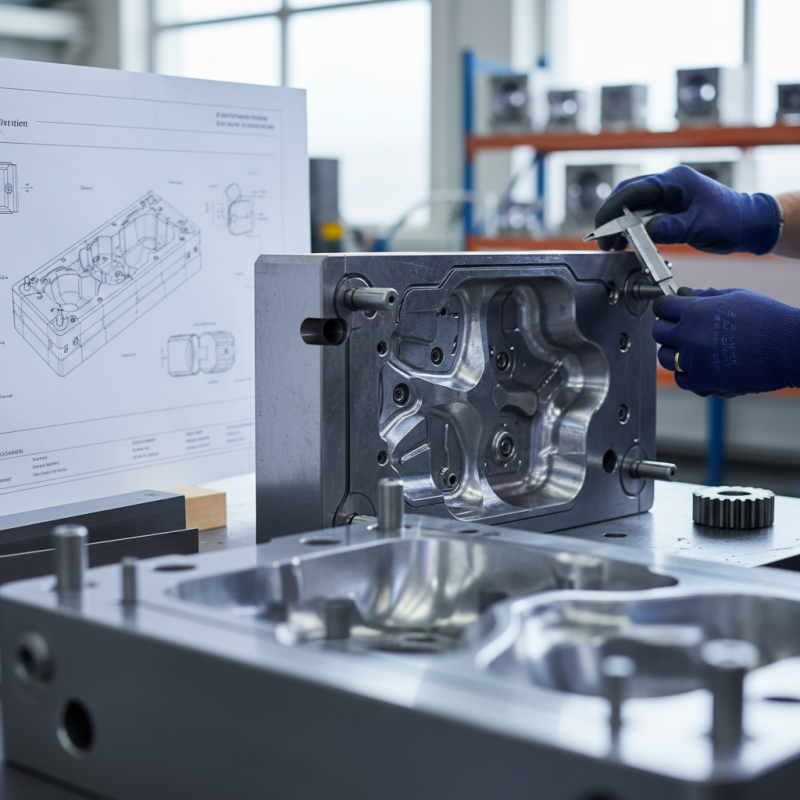

Die casting molds play a crucial role in manufacturing processes. They are essential for creating complex shapes with high precision. Understanding their functionality is key to optimizing production efficiency. According to a report by the Die Casting Industry Council, over 1.5 million tons of die castings are produced annually. This highlights the importance of selecting the right molds for projects.

Choosing the appropriate mold requires careful analysis. The mold's design affects material flow and cooling times. A poorly designed mold can lead to defects, resulting in increased costs. A study from the International Journal of Advanced Manufacturing Technology revealed that defects can lead to a 15% increase in production costs. Choosing a mold with the right surface finish is vital. It impacts the final product’s quality and appearance.

When evaluating die casting molds, consider the material and design. Aluminum alloys are the most common choice, known for their lightweight and corrosion resistance. However, some projects may require heavier materials. Finding the balance between durability and cost is necessary. Reviews show that efficiency often falls short when molds aren’t designed adequately. Addressing these issues early can save time and resources down the line.

Factors to Consider When Selecting Die Casting Molds

Choosing die casting molds requires careful consideration of several factors. Parameters like material choice play a crucial role. Aluminum alloys dominate the industry, accounting for about 80% of die castings. They provide lightweight properties and good corrosion resistance. However, zinc and magnesium alloys have their own benefits, such as higher strength. It's essential to match the alloy to your project's specific needs.

The complexity of the part is another key factor. The design must allow for efficient flow of molten metal. Intricate shapes may cause issues during the casting process. For instance, undercuts can complicate ejection. According to industry reports, 25% of defects arise from design flaws. Consider the draft angles and wall thickness carefully. These aspects impact the mold's longevity and production efficiency.

Cost is a significant consideration, too. Molds can be expensive, with estimates ranging from 5,000 to over 100,000 USD depending on design complexity. Think about the return on investment. Can you afford to run multiple iterations if the initial design fails? Balancing initial costs against potential production efficiency is crucial. Evaluate these factors consistently.

Types of Die Casting Molds Suitable for Various Projects

When selecting die casting molds, understanding the types available is crucial. There are several common types of molds used in various projects. Each serves a specific purpose, and choosing the right one can impact production quality.

For instance, cold chamber molds are often ideal for metals with high melting points. They provide excellent precision, but they might limit the speed of production. Hot chamber molds, on the other hand, are faster and can handle lower melting metals. However, this comes at the risk of wear and tear. The mold material matters too. Steel molds are durable but can be expensive. Aluminum molds are cheaper but may not withstand high-volume production.

Another point to consider is the mold design. Complex designs can lead to difficulties in the casting process. They may require detailed planning and additional machining. Simplicity often helps improve efficiency, but it could sacrifice some design elements. Balancing these factors is essential. Not every project will have the same needs or constraints. Reflecting on these differences can lead to better outcomes in your die casting endeavors.

How to Choose Die Casting Molds for Your Projects?

| Mold Type | Suitable Materials | Applications | Benefits |

|---|---|---|---|

| Hot Chamber Molds | Zinc, Magnesium | Automotive parts, Electrical components | Faster cycle times, Cost-effective for small parts |

| Cold Chamber Molds | Aluminum, Copper | Heavy machinery, Aerospace parts | Higher melting points, Better for high-performance applications |

| Die Casting Inserts | Various alloys | Consumer goods, Complex designs | Customization options, Enhanced design flexibility |

| Multi-Cavity Molds | Aluminum, Zinc | Mass production, Hardware components | Increased output, Cost efficiency for large runs |

Evaluating Material Choices for Die Casting Molds

When selecting materials for die casting molds, it’s essential to consider several factors. The choice of material significantly affects the mold's durability and performance. Some popular materials include aluminum, steel, and zinc alloys. Each material has its unique properties. Aluminum molds are lightweight and offer good thermal conductivity. However, they may wear out faster than steel molds with prolonged use.

Steel molds, on the other hand, are robust and long-lasting. They handle high temperatures well. But they can be heavier and more expensive. Another option, zinc alloys, provides excellent dimensional accuracy and surface finish. Yet, they might not withstand high-volume production like steel. It’s crucial to analyze the production needs before making a decision.

The environment where the molds will be used also plays a role. High-temperature processes can impact material choice. Consider the potential for corrosion as well. Each option has limitations. Reflecting on these aspects ensures better outcomes. Weighing the pros and cons helps avoid poor material choices. Achieving the right balance can be challenging, but the right material ultimately enhances the die casting quality.

Material Choices for Die Casting Molds

Best Practices for Maintaining and Storing Die Casting Molds

Maintaining and storing die casting molds is crucial for ensuring their longevity and effectiveness. When not in use, molds should be stored in a clean, dry space. Humidity can cause rust and damage. Place molds on racks, avoiding direct contact with the floor. Extreme temperatures can warp the shapes.

Regular inspection is essential. Check molds for wear or damage every few months. Look for cracks or shifting components. Small issues, if left unchecked, can lead to larger problems. Lubricate moving parts to keep them functional. It’s necessary to address these routine checks diligently.

Proper cleaning is also vital. After each use, remove any residual metals or debris. Use non-abrasive cleaners to prevent scratches. Improper cleaning can lead to poor casting quality later. Organize your storage area to easily locate each mold. This step will save time and reduce frustration when starting new projects.